Last updated: August 23rd, 2024

Last updated: August 23rd, 2024

Know Your Pool Pumps: 101 Guide

A sparkling pool adds beauty and recreation to your backyard, but keeping it that way requires a dedicated workhorse – the pool pump. This unsung hero silently circulates water through the filter system, ensuring clean, healthy water for swimming.

But like any machine, pool pumps don’t last forever. Knowing the problems, when to replace them, and proper maintenance practices can save money, prevent more significant issues, and keep your pool paradise pristine. Let’s begin!

Understanding Your Pool Pump

What it Does

Imagine your pool as a giant living organism that needs constant circulation to stay healthy. The pool pump acts as the heart of this system. It continuously draws water from the pool through a skimmer basket and main drain. This water gets pushed through the filter, where impurities like leaves, algae, and debris get trapped. Finally, the clean water is returned to the pool, completing the vital filtration cycle.

How it Works

Most pool pumps are centrifugal, relying on a simple yet effective design. Here’s a breakdown of the key components:

- Impeller: This spinning disc is the heart of the pump. As it rotates rapidly, it creates a suction that draws water into the pump.

- Volute: This spiral-shaped casing surrounds the impeller and helps direct water flow efficiently.

- Motor: Powered by electricity, the motor provides the energy to spin the impeller and keep water circulating.

- Strainer Basket: Located at the pump’s intake, this basket captures large debris before it enters the impeller and potentially causes damage.

Types of Pool Pumps:

There are two main types of pool pumps available:

- Single Speed Pumps: These are the most common type and offer a constant flow rate. They are generally more affordable but less energy-efficient.

- Variable Speed Pumps: These pumps allow you to adjust the flow rate to suit your needs. They are more energy-efficient than single-speed pumps but have a higher upfront cost.

Top 5 Problems With Pool Pumps

Don’t let a pump malfunction turn your pool paradise into a stagnant puddle!

Here’s a breakdown of the top 5 pool pump problems and how to identify and fix them:

- The Silent Treatment: No Power at All

This is the most obvious issue and often the easiest to fix.

- Check the Breaker: First, head to your electrical panel and ensure the breaker for your pool equipment hasn’t tripped. Reset it if necessary, but if it trips again, consult an electrician.

- Power Cord Blues: Inspect the power cord for any damage or loose connections at the outlet or pump. A damaged cord needs to be replaced by a qualified professional.

- Control Panel Check: If you have a pool control panel, ensure it’s functioning correctly and the pump is set to “on.”

- The Whisper Becomes a Roar: Unusual Noises

Strange noises emanating from your pool pump are a red flag. Here are the culprits behind the racket:

- Grinding or Screeching: This could indicate worn bearings or a failing motor. Shut off the pump and call a professional for repairs.

- Loud Rattling: If the pump sounds like it’s shaking a maraca, it might be improperly seated on its base. Ensure the pump is level and rests securely. Placing it on a rubber mat can also help dampen vibrations.

- Gurgling: A gurgling sound often signifies air entering the system. Check the water level in your pool skimmer – it should be at least halfway up the skimmer basket. If the water level is good, there might be a leak on the suction side of the plumbing.

- Weak Flow: Not Pulling Its Weight

A weak water flow from your pool jets indicates your pump isn’t circulating water efficiently. Here’s what could be causing the sluggishness:

- Clogged Basket: The most common culprit is a basket overflowing with leaves and debris. Remove the basket and thoroughly clean it.

- Blocked Impeller: Sometimes, debris can get past the basket and jam the impeller. Shut off the pump and consult your manual for instructions on safely removing and cleaning the impeller.

- Clogged Filter: A clogged filter restricts water flow. Clean or replace your filter cartridge according to the manufacturer’s instructions.

- The Drippy Dilemma: Leaks Around the Pump

Leaks around your pool pump are a sure sign something’s amiss. Don’t ignore them!

- Worn Seals: Seals around the pump housing can deteriorate and leak over time. Replacing worn seals requires technical expertise, so call a professional for this fix.

- Loose Connections: Pipes connecting to the pump might have loosened, causing leaks. Tighten loose fittings with appropriate wrenches, but be cautious not to over-tighten and damage the threads.

- Rising Energy Bills: Working Overtime

An old or inefficient pool pump will use more energy to circulate the same amount of water, leading to higher electricity bills. Consider these options:

- Upgrade to a Variable Speed Pump: These pumps allow you to adjust the flow rate, using less energy when filtration needs are lower.

- Schedule Regular Maintenance: Proper maintenance keeps your pump running efficiently.

Maintaining Your Pool Pump for Optimal Performance

Like any hardworking machine, your pool pump needs regular maintenance to function optimally and last as long as possible. Here are some key maintenance practices:

- Cleaning the Basket: Regularly remove and clean the strainer basket to prevent debris from accumulating and restricting water flow.

- Skimming the Surface: Skimming the pool surface regularly removes leaves and debris before they reach the pump, reducing strain on the system.

- Maintaining Water Levels: Ensure proper water levels to avoid the pump running dry or working harder than necessary.

- Lubrication: Some pumps require periodic lubrication according to the manufacturer’s instructions. This helps to reduce friction and wear on internal components.

- Visual Inspection: Regularly inspect the pump housing for leaks, cracks, or loose connections.

- Professional Inspection: Schedule an annual inspection by a pool professional to identify potential issues before they escalate into major problems.

By following these simple maintenance routines, you can extend the lifespan of your pool pump, ensure efficient operation, and keep your pool sparkling clean.

Understanding When Your Pool Pump Needs Replacing

Despite your best efforts, pool pumps eventually wear down due to constant use and exposure to the elements.

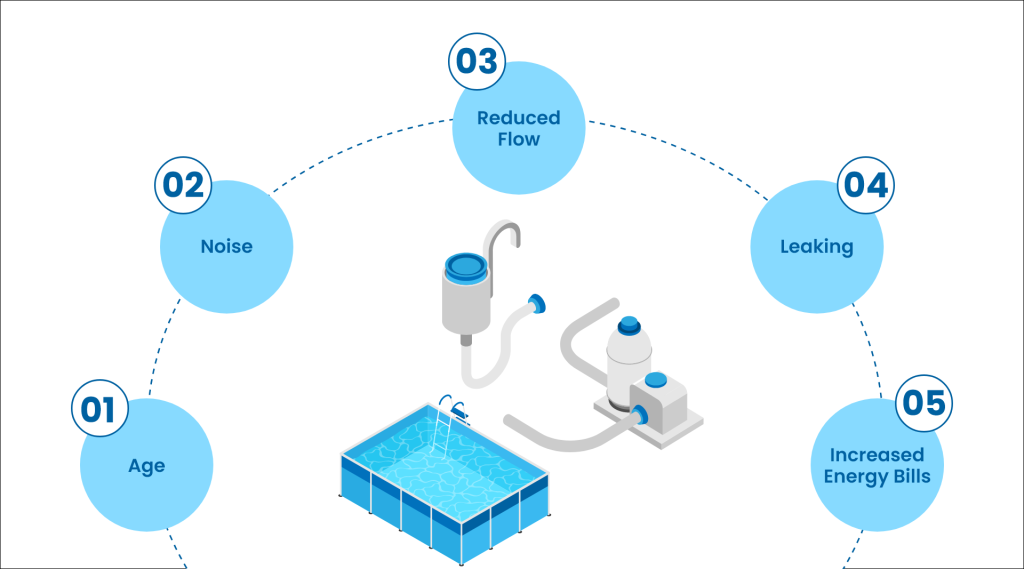

Here are some signs that your pool pump might be nearing the end of its lifespan:

- Age: Pool pumps typically have a lifespan of 8-12 years. If your age is approaching, consider proactive replacement to avoid unexpected breakdowns during peak swimming season.

- Noise: Unusual noises emanating from your pool pump are a red flag. Listen for grinding or screeching sounds, which can indicate a failing motor, worn bearings, or other internal problems. These noises signify a pump nearing the end of its lifespan and needing attention.

- Reduced Flow: A noticeable decrease in water flow from the pool jets or returns suggests the pump might not function at full capacity. This could be due to a failing pump or clogged components, but a significant drop in flow often indicates a pump nearing its replacement time.

- Leaking: Leaks around the pump housing are a red flag and could indicate worn seals or damaged components. These leaks waste water and signal potential internal issues within the pump itself.

- Increased Energy Bills: An old and inefficient pump will use more energy to circulate the same amount of water, leading to higher electricity bills. While regular maintenance can help optimize pump efficiency, a significant and unexplained increase in energy costs could indicate that your pump is working overtime to compensate for internal wear and tear.

If you experience these signs, consult a pool professional to diagnose the issue and determine if a replacement is necessary.

Taking Action: What to Do When Replacement is Necessary

If you’re experiencing one or more of the signs mentioned above, it’s time to consult a pool professional. They can diagnose the problem and determine whether a repair or replacement is the best action. Here are some next steps to consider:

- Seek Professional Help: A qualified pool technician can accurately diagnose the issue and recommend the best solution. They can also handle the replacement process efficiently and ensure your new pump is installed correctly.

- Research Replacement Options: With various pool pump models available, discuss your needs and budget with your pool professional. Consider energy-efficient variable speed pumps for long-term savings.

- Home Warranty as a Safety Net: A home warranty that includes pool equipment coverage can offer financial protection in case of a major pool pump malfunction. Review your warranty plan to understand coverage details and the claims process.

4 Best Home Warranty Companies For Pool Pumps

A home warranty with pool equipment coverage can offer valuable protection and peace of mind. Here are the top-rated home warranty companies that offer comprehensive, reliable coverage for pools.

|

Company |

Pool Coverage Details |

Additional Benefits |

Premiums |

|

|

Up to $3,000 coverage for pool equipment breakdown (may vary by plan) |

Covers a wide range of appliances and systems in the home. Offers optional roof leak coverage. |

$29 – $89 |

||

|

Up to $1,500 coverage for pool pumps and other saltwater pool equipment |

Offers various plans with different coverage levels and customizable options. Features a mobile app for easy claim submission. |

$50 – $60 |

||

|

Offers an affordable add-on package for pool equipment coverage |

Known for its competitive pricing and transparent plans |

$38 – $66 |

||

|

Up to $1,000 coverage for pool pumps and other pool equipment |

Offers a satisfaction guarantee and multiple plan options |

$50 – $62 |

Conclusion

By understanding the role of your pool pump, maintaining it properly, and recognizing the signs of wear and tear, you can make informed decisions about replacement. A home warranty can also offer valuable protection and peace of mind if your pool pump needs to be replaced. With the right knowledge and planning, you can keep your pool sparkling and your wallet happy for many years.

related articles

Discover First American Home Warranty Locations and What You Need to Know About Their Cover.

Discover First American Home Warranty Locations and What You Need to Know About Their Cover.

Reviews of Home Warranty Companies Show You How to Determine If Your Home Is Covered

Reviews of Home Warranty Companies Show You How to Determine If Your Home Is Covered